In the 1970s, Tong Lianshan, the founder of Kesai, conducted research on fluorinated polymer materials and their applications in China, with an annual production capacity of 5000 tons of high-performance engineering materials. The company has evolved from a single product in the early stages of entrepreneurship to a diversified product now, from a manufacturer solely supplying PTFE material products to a one-stop solution supplier providing customers with various special engineering materials.

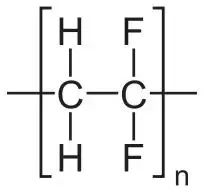

After the successful launch of the PEEK series products, Kesai has also successfully launched a special engineering plastic, which is the second largest production of fluorinated plastics - polyvinylidene fluoride, abbreviated as PVDF.

Product Introduction

PVDF is a thermoplastic engineering plastic formed by free radical polymerization of VDF monomers, which has excellent comprehensive properties, wide applications, and combines the characteristics of fluoroplastics.

Due to its gapless spatial barrier, no atoms or groups can enter its internal structure to destroy the carbon chain, thus exhibiting extremely high chemical and thermal stability.

In addition, PVDF has excellent resistance to oxidation, ultraviolet radiation, and high temperature radiation, as well as excellent tensile and impact strength. It has high hardness and wear resistance, high thermal deformation temperature, and excellent creep fatigue resistance. Its operating temperature range is -60~150 ℃, making it a strong and tough structural material.

Product raw materials

The main traditional manufacturers of global polyvinylidene fluoride (PVDF) include Acoma, Solvay, San'aifu New Materials, and Dongyue Group.

.jpg)

Product application

Based on the excellent product performance of PVDF, its applications can be mainly divided into industries such as petrochemicals, pan semiconductors, electronics and electrical, coatings, etc.

Petrochemical industry

PVDF has excellent chemical resistance and processability, as well as resistance to fatigue and creep. Therefore, PVDF is widely used in pumps, valves, pipelines, pipeline fittings, storage tanks, and other fluid treatment systems of petrochemical and other industrial equipment as a whole or lining.

.png)

Pan semiconductor industry

The material requirements for related equipment in semiconductor manufacturing are very high, mainly including roughness, chemical stability, electrical insulation, etc. PVDF has good chemical stability, electrical insulation performance, and flame retardancy, and is widely used in production process equipment in the semiconductor and photovoltaic industries, such as storage containers for high-purity chemicals, valves for transportation, pipelines, and pipeline accessories.

.jpg)

The electronic and electrical industry

PVDF has insulation properties, corrosion resistance, self extinguishing, aging resistance, and easy processing. It can be used to manufacture special wires and cables, joints, sheaths, cathodic protection sleeves, etc. In addition, PVDF has excellent corrosion resistance and chemical stability. Porous films, gel, diaphragms, etc. made of PVDF resin are used in lithium batteries, photovoltaic backplane films and other products to manufacture potassium battery diaphragms and membrane coatings.

.png)

PVDF is one of the commonly used main raw materials for fluorocarbon coatings. Due to its strong weather resistance, PVDF resin can be used outdoors for a long time. This type of coating is often used in outdoor buildings, such as power plants, airports, highways, high-rise buildings, etc.

Other industries

PVDF can produce various porous and non porous materials, which can be applied in the field of biomedical devices. PVDF hollow fiber membrane can be applied in the field of water treatment.

Kesai products

The CONCE ® PVDF product series includes plates, rods, welding rods, etc., with a variety of specifications and varieties. CONCE ® PVDF products balance performance and color. Carefully select brand raw materials and strictly control all aspects of production. The product has passed certifications such as RoHS and REACH. Kesai products have outstanding advantages:

01

The product has good dimensional stability, excellent mechanical performance, and outstanding processing performance. The optimized production process ensures product quality

02

High batch stability and traceability.

03

Has strong development capabilities and can cooperate with clients for development work.

04

The mold specifications are complete and can be customized for production according to customer needs

.jpg)

Note: For detailed product dimensions, please consult separately (the above images are all online images. If there is any infringement, please contact us immediately to delete them))