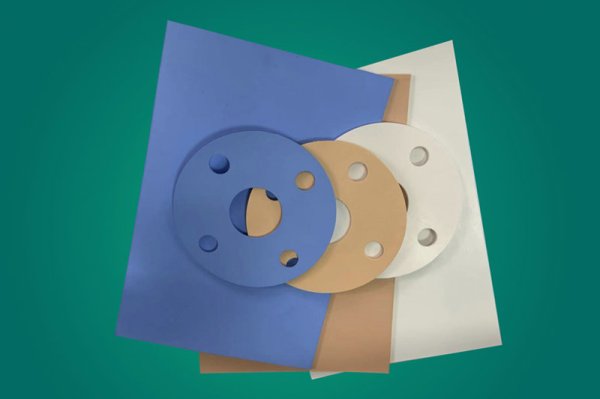

PTFE Sheet

CONCE ® PTFE-G9598

Product features:

Tightest sealing, reduces creep relaxation, excellent screw torque retention performance, and chemical resistance

Applicable working conditions (medium):

Moderate concentration of acid, some corrosive substances, hydrocarbons, dissolution, water, refrigerant, low-temperature substances, hydrogen peroxide; Acetic acid, pharmaceutical cleaning pipelines, glass lined flanges with good surface roughness, defective and uneven flanges, heat exchangers, etc.

Product Usage:

Chemical, pharmaceutical, etc

CONCE ® PTFE-G9597

Product features:

Tightest sealing, reduces creep relaxation, has good leakage resistance, and chemical resistance

Applicable working conditions (medium):

Strong acids (excluding hydrofluoric acid), solvents, hydrocarbons, water, steam, chlorine, low temperature; Polycrystalline silicon, under acidic conditions (excluding hydrogen nitrogen acid).

Product Usage:

Chemical industry

CONCE ® PTFE-G9599

Product features:

Tightest sealing, reduces creep relaxation, and has chemical resistance

Applicable working conditions (medium):

Strong corrosive substances, neutral acids, chlorine, coal gas, water, steam, hydrocarbons, low-temperature substances, aluminum fluoride alkalinity, and fluorine-containing environments.

Product Usage:

Chemical, pharmaceutical, etc

Main technical indicators:

| unit | standard | CONCEPTFE-G9598 | CONCEPTFE-G9597 | CONCEPTFE-G9599 | |

| colour | - | Na | blue | yellow | white |

| density | g/m³ | ASTM D792 | 1.55-1.65 | 2.1-2.3 | 2.1-2.3 |

| Filler | - | nothing | Glass microbeads | silicon dioxide | barium sulfate |

| tensile strength | - | ASTM F152 | ≥8 | ≥8 | 10 |

| compression ratio | - | ASTM F36 | ≥16 | ≥10 | 8 |

| Compression rate and rebound rate | - | ASTM F36 | ≥26 | ≥30 | 27 |